Last Updated on January 29, 2024

Have you ever dreamt of a home that requires little to no maintenance? Never needs to be painted? Yeah, me too….. For about 2-3 years after the end of World War II, not only did this type of house exist, but were marketed to Americans as the epitome of hassle-free living (I like the sounds of that…). Let’s dive into the rise and fall of these mass-produced, all-metal Lustron Homes.

Background

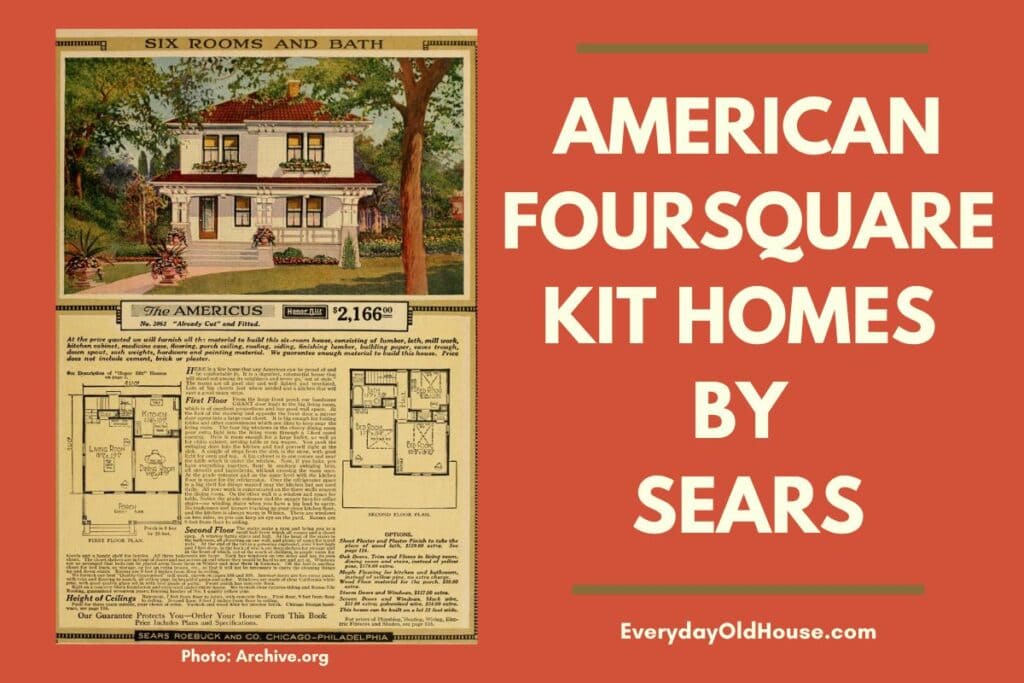

If you follow this blog, then you probably know my interest the history of old houses, including kit houses. I find it fascinating that over 100 years ago, before tech, you could literally pick out an entire house in a catalog and have it delivered to build.

Catalog companies like Sears, Montgomery Ward and Aladdin would sell you a “kit” with all the parts to build your own house – roofing, nails, wood, flooring, paint, even plumbing fixtures. All with an nice detailed instruction booklet. IKEA has nothing on these guys….

But last week I learned about a different type of “kit” house on one of my favorite podcasts – True Tales from Old Houses. Lustron Homes, popular about 50 years after the height of kit houses. Similar in that all the parts needed to build a house were packaged and shipped to a homeowner, BUT Lustron’s claim to fame was their building material – porcelain enameled steel (versus timber).

My curiosity peaked, I dove more into history to find these 12 interesting facts about these enameled steel houses.

1. What Are Lustron Homes? How are they Unique?

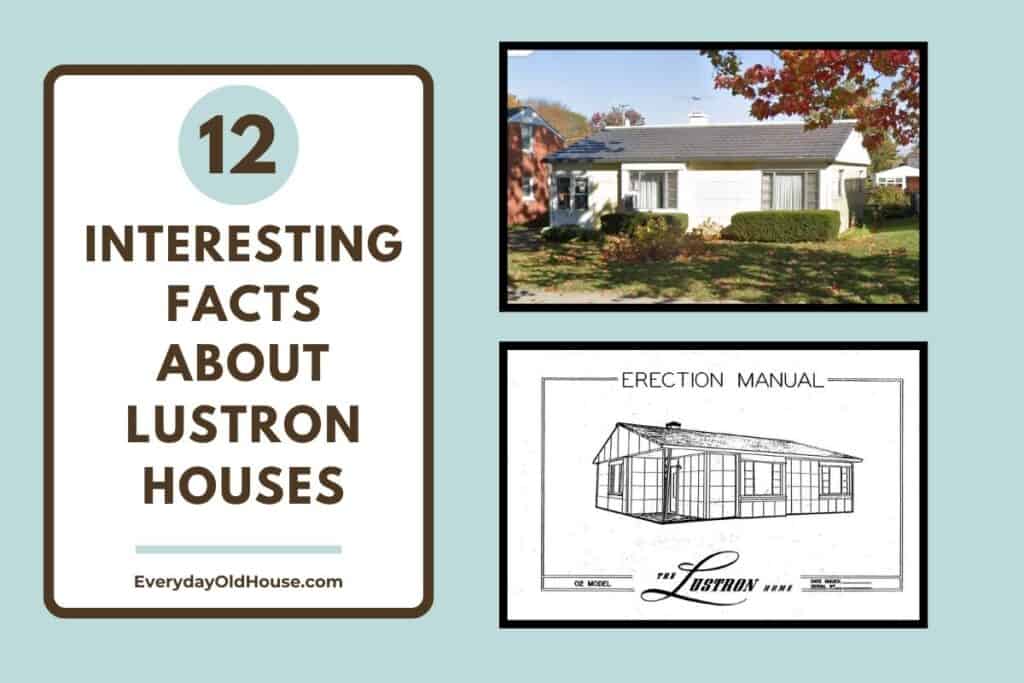

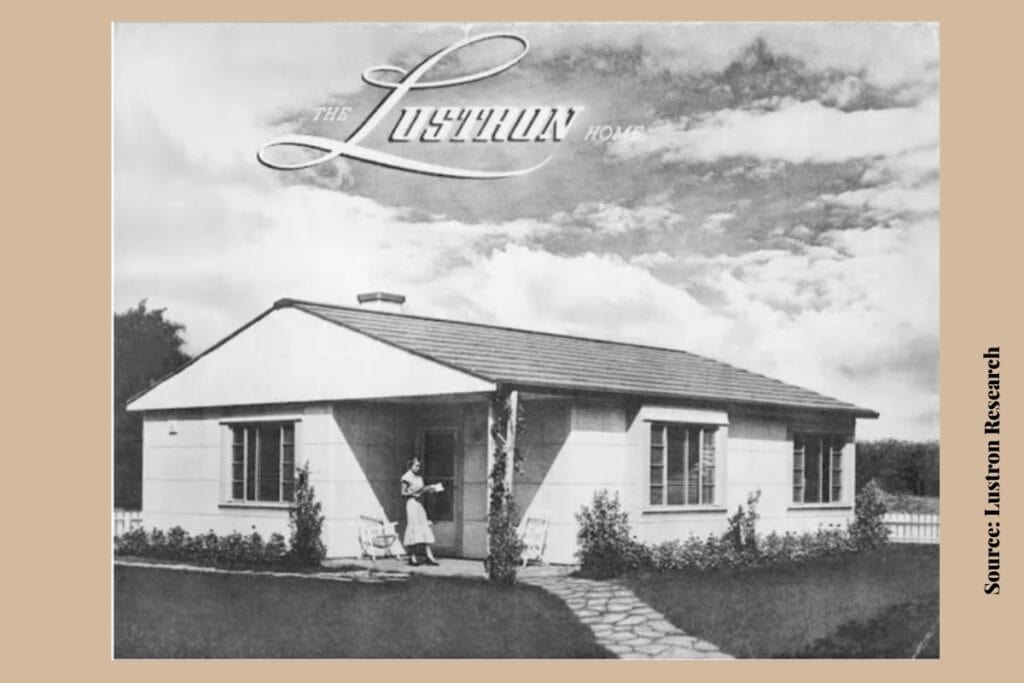

Lustron homes differed from the traditional stick frame homes in that they were made from the revolutionary use of prefabricated enameled steel. From roofing, frame, architectural porcelain enamel wall panels, all the way down to built-in cabinets and furniture.

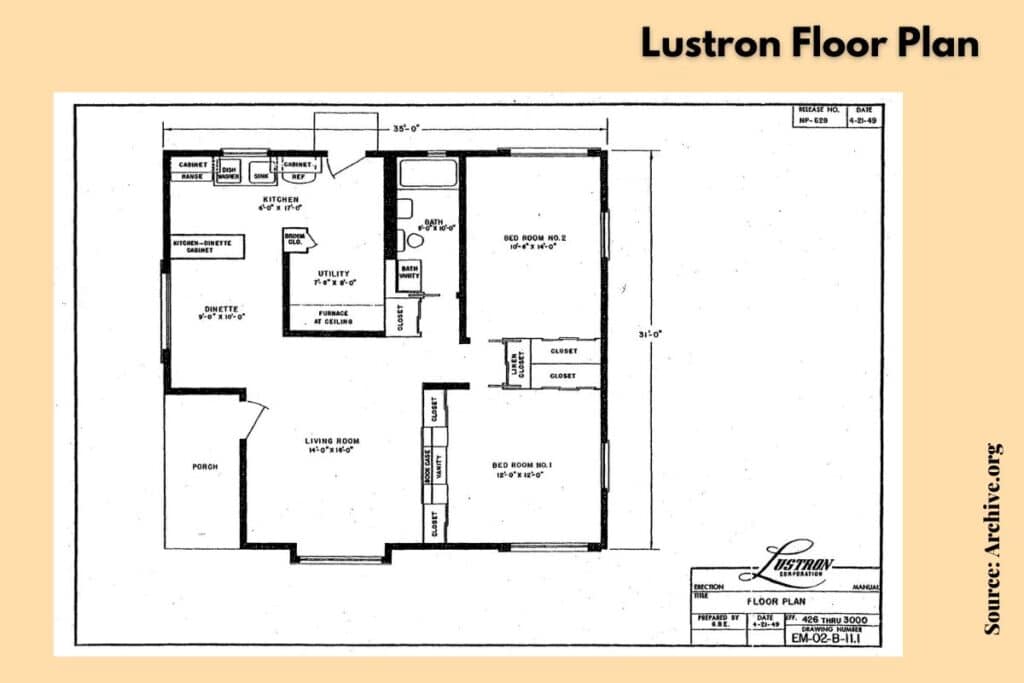

These houses were one-story, ranch style, no basement with a gable roof, usually with a bay window and side porch. Typically, they were around 1,000 ft2 and had 2 bedrooms (with an option for 3 bedrooms), which was usual for all houses built at that time.

The name “Lustron” was developed after the procedure of literally putting “luster on” steel during the enameling process.

As you’ll read below, each component, from the walls to the roof, was manufactured in assembly line style, ensuring uniformity and quality. The average house consisted of about 3,300 parts, totaling about 12 tons of steel and 1 ton of enamel.

2. Why were Lustron Homes Created?

After the end of World War II, millions of G.I.s returned home to the United States with the dream of buying a house, settling down, and starting a family. But there was a problem – there weren’t enough houses.

G.I. were sleeping in cars, garages, attics, boxcars, even chicken coops! So the federal government, under President Truman, launched emergency programs to find a solution to address the extreme housing shortage. And a potential answer to efficient affordable housing? Mass-production of homes.

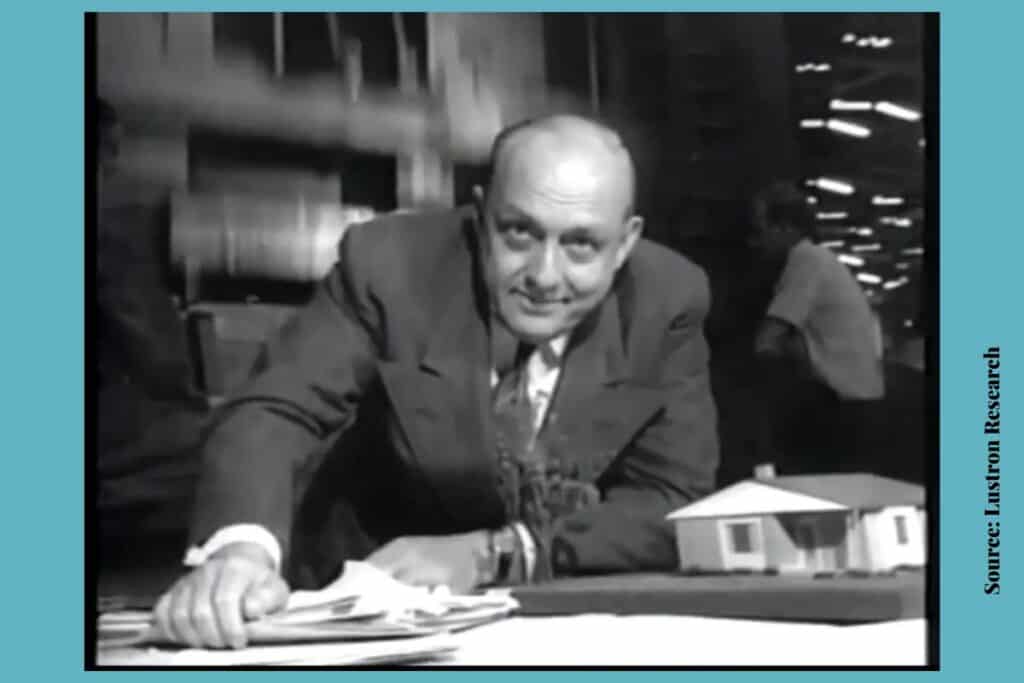

Enter inventor Carl Strandlund, a Chicago industrialist, and brainchild behind Lustron Homes.

He unveiled a groundbreaking concept – homes made entirely of prefabricated steel – which allowed for mass-produced housing and quick assembly. His vision was to adapt the principles of the automobile industry. Which meant building a few models of houses in an assembly line at a factory. And as with automobiles, ship it to a dealer who would erect it for a homeowner.

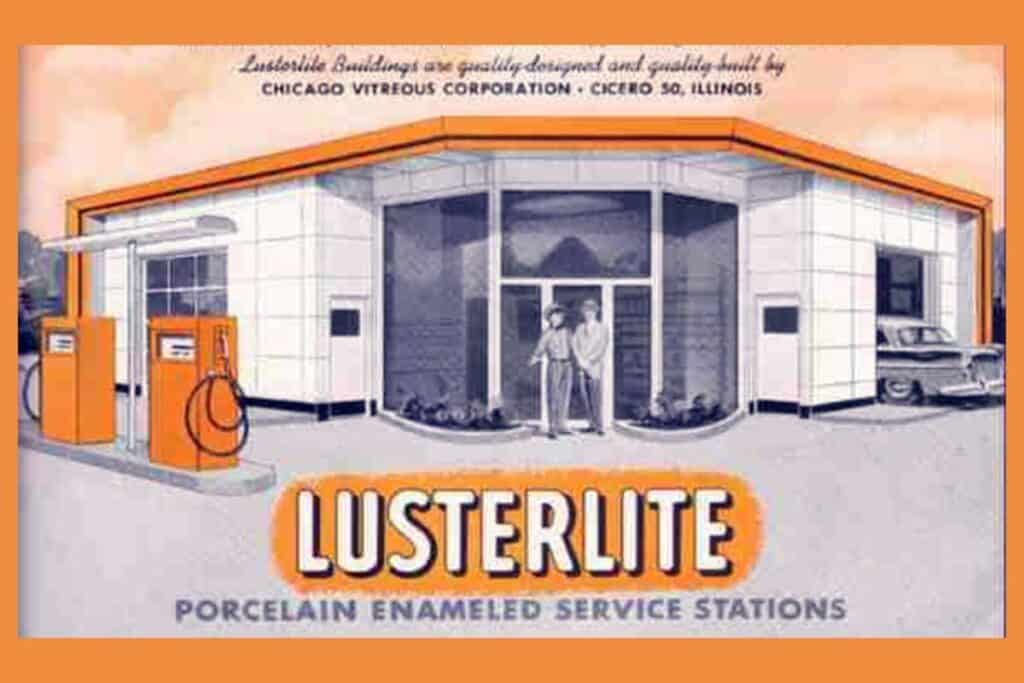

In his previous work at the Chicago Vitreous Enamel Corporation, he had successfully used prefabricated porcelain-enameled panels to build gasoline stations and restaurants. So why not houses?

And this groundbreaking concept convinced the federal government under the Reconstruction Finance Corporation to invest in Lustron Corporation (a division of the Chicago Vitreous Enamel Corporation) with a $40 million loan to fix the veteran housing crisis.

3. Why were Lustron Homes So Popular?

Lustron homes believed that they would emerge as a popular choice for prospective homeowners for several reasons.

Quick Assembly

Carl Standlund anticipated that the prefabricated steel construction method allowed for a faster assembly compared to traditional building techniques, meeting the urgent need for housing. And if you’re sleeping on your in-laws couch because you can’t find a house, fast assembly is pretty tempting….

Modern Conveniences and Low Maintenance

The Lustron innovation aimed not only to meet the demand for housing but also to introduce a new level of convenience and durability to homeowners.

After the hard, lean years of World War II, people wanted to catch up on fun and spend more time on leisure activities, family time and carefree living. Post-war optimism was about leaning into pursuits that weren’t available during the hardships of WWII.

Homeowners were attracted to the perceived time- and space-saving features of a Lustron home. Owning in a Lustron home wasn’t just about having a house; it was an experience, marked by the unconventional yet inviting atmosphere created by the innovative design. It was “the house America was waiting for”.

The enameled steel surfaces made cleaning a breeze, reducing the maintenance burden on homeowners. Because the interior and exterior finishes were baked on, it never faded and homeowners never have to paint. You literally cleaned the exterior with a garden hose, interior with soap and water.

Plus, as an added bonus, surfaces were immune to rust, decay, rodents, termites and fire.

To accentuate modern living and efficient use of space, Lustron homes incorporated built-in features such as cabinets, shelves, and even furniture like in the photo below.

There was even an “Thor” combination clothes- and dishwashing machine located in the kitchen, pulling double- duty cleaning. I wish I had that!!

4. Where were Lustron Homes Manufactured?

In 1947, Carl Strandlund set up the Lustron’s headquarters in Columbus, Ohio. They leases a World War II airplane plant assembly plant from the United States government.

The plant was HUGE. It was approximately 1 million square feet on 106 acres. At peak production, the plant used more electricity than the rest of Columbus.

While Columbus served as the heart of Lustron production, there were a few satellite factories in Chicago, Illinois, and Omaha, Nebraska to foster efficient production and timely delivery of the soaring demand of Lustron homes in other parts of the country.

5. What Lustron Models Were Available?

Carl Strandlund and his team introduced these 3 main models of Lustron homes, each showcasing specific features and layouts. Customization, while available, was rare.

While all Lustron models shared the common thread of prefabricated steel construction and features like space-saving pocket doors, each had its own set of characteristics. From the layout of rooms to the placement of windows, these features catered to diverse homeowner preferences.

Westchester

The flagship model, the Westchester (floor plan shown above) was known for its spacious design and additional features. It was the most popular model. There was also the Westchester Deluxe model appealed to those families with larger space requirements, with an extra bedroom and additional built-in storage.

Meadowlark

A more compact option, the Meadowlark retained the essential Lustron features in a smaller footprint. Ideal for individuals or small families, it offered a cozy yet functional living space.

Newport

Recognized for its distinctive front entrance, the Newport model showcased Lustron’s commitment to innovative design. The unique entryway added a touch of architectural flair with a zigzagged trellis.

For paint colors, there were 4 non-fading exterior colors and 2 interior paint colors options available:

- Surf Blue

- Dove Gray

- Maize Yellow

- Desert Tan

It isn’t 100% clear to me, but it appears that homeowners worked with a dealer to buy their Lustron house. Similar to buying a car, you would work with a dealer to pick out your model and have it shipped and constructed on your property.

6. How were Lustron Homes Built?

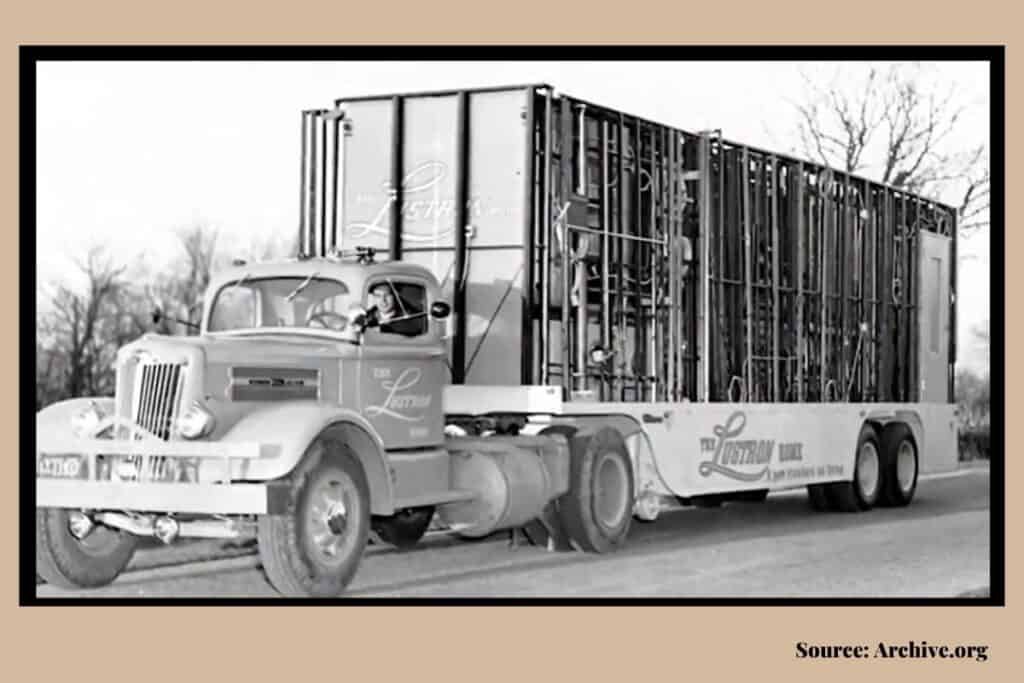

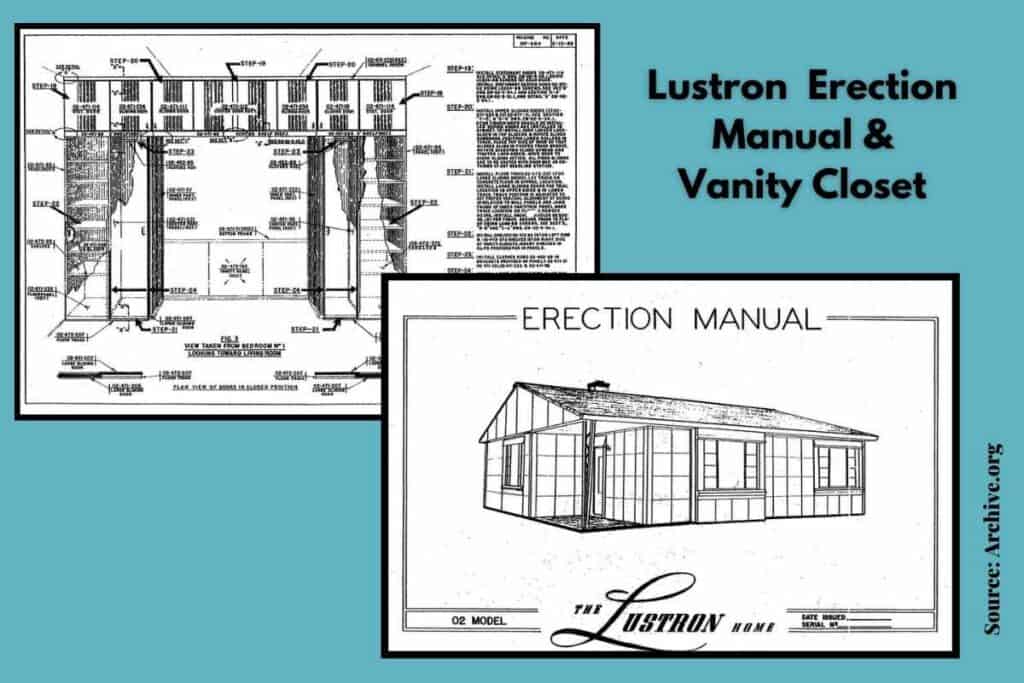

Lustron homes were designed to essentially be giant steel puzzles. Prefabricated steel elements, including walls, roof, and even interior fixtures, were manufactured at the factory and numbered for assembly. As we touched on above, the average Lustron house had about 3,300 parts. Yikes!

Once all the components were ready, the unassembled houses were shipped to a homeowner’s property using a specialty designed tractor-trailer like the one pictured below.

At the property, a team of workers, used detailed instructions to piece together the steel structure. The erection manual pictured below was about 400 pages (a bit longer than the manuals from IKEA…).

The assembly process seems to akin to building a Sears mail order house. However, kit houses used traditional materials and assembly techniques, while Lustron did not.

Since the construction process didn’t involve any modification of materials (like traditional stick frame houses that involved cutting lumber), a fully constructed Lustron home could be ready for occupancy in a matter of days to two weeks.

7. How Much did Lustron Homes Cost?

Lustron homes were originally marketed as an affordable housing solution. Standardizing the production process and using prefabricated components expected to equate to cost savings which would result in lower, competitive house prices.

A report at the beginning of Lustron’s federal government loan funding and design process estimated the cost for a Lustron home around $4,800. This was ideal, considering the federal government estimated that the average middle-class family and returning Veterans could afford around $5,000.

And while this cost didn’t include the additional $2,000 estimate to install the home’s concrete slab foundation and other infrastructure, it was still regarded as a good value compared to the traditional stick frame homes.

Plus, the Lustron Corporation offered financing options, allowing more post World-War II families to reach and attain their dream of homeownership.

A win-win situation, right?

However, as you’ll learn further down, once the rubber hit the road, the price of a Lustron home was well underestimated. Once the rubber hit the road and Lustron was in production, the company needed to increase their asking price tag to DOUBLE their original estimate. And for obvious reasons, that accelerated the company’s demise.

8. When were Lustron Homes Built?

The construction years of Lustron homes spanned a relatively short timeframe. The peak of Lustron home construction occurred in 1949 to 1951.

9. How Many Lustron Homes Were Built? How Many Remain?

Approximately 2,500 to 2,680 Lustron homes were built between 1948 and 1954. A drop in bucket to the 20,00 “firm orders” that Strandlund claims to received.

Luckily, according to Wikipedia, a significant number – 2,000! – are expected to still remain. It should be noted that some have significantly been altered.

However, I fear that the average American (including myself!) aren’t aware of Lustron homes’ architectural significance. Hopefully, these smaller homes aren’t quietly demolished and replaced with new, larger homes.

10. Where are Lustron Homes Located?

While Lustron homes were advertised from coast to coast, most were concentrated in the Midwest, particularly in states like Ohio, Indiana, and Illinois. It’s theorized that the heavy weight of the 12 tons of steel made it near impossible to transport over the Rockies to the West Coast.

However, there were a significant number built in Virginia to support the influx of new workers near the nation’s capital. For example, in 1948 about 60 Lustron homes were built at the Marine Corp base in Quantico, VA.

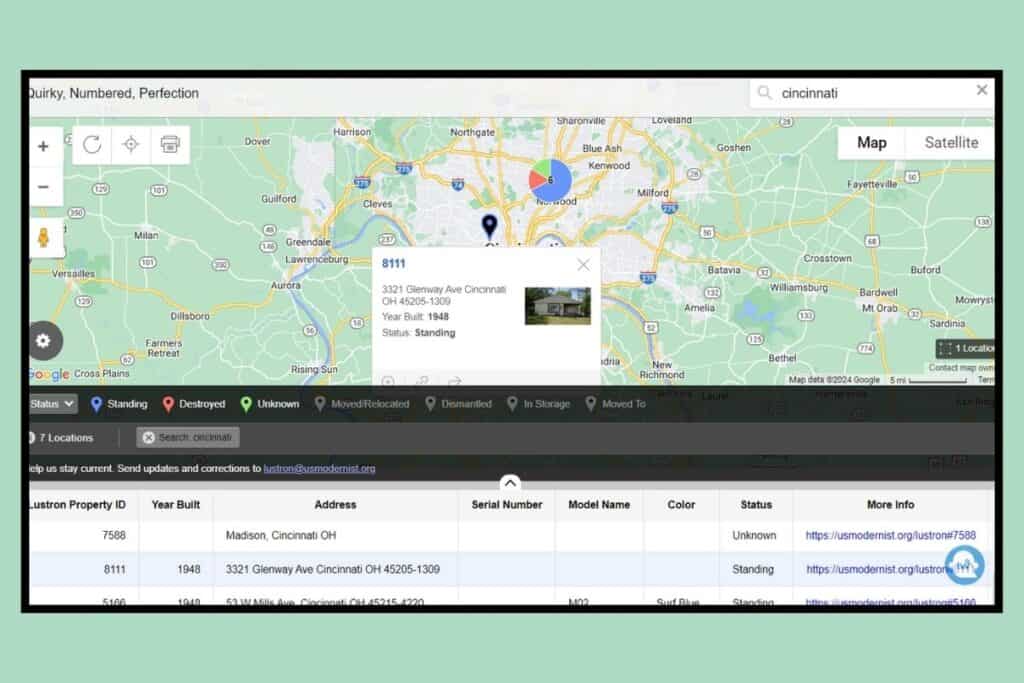

The National Lustron Map is an amazing database if you want to dive deeper into locations of Lustron homes (and see if any are located near you.)

The site, a collaboration between Lustron Research and US MODERNIST group, has a Google-based map of Lustron homes around the country. It’s amazingly detailed, with addresses, Lustron model number, original color, serial number and whether or not the house still exists. There are even photos of individual homes.

11. Why did Lustron Houses Fail?

The Lustron Corporation faced several challenges that ultimately led to its closure. Despite initial success and widespread interest in Lustron homes, the company encountered financial difficulties, production issues, and competition from traditional homebuilders that led its decline and eventual closure in the early 1950s.

Manufacturing Woes

Lustron estimated a theoretical manufacturing goal of 100 houses per day, 2,500 per month, and 30,000 a year. But due to production problems, they never even made it close. At its peak, the manufacturing facility only reached 27 houses per day. Whoops….

Financial Issues

Even for a few years after World War II, steel was still allocated to corporations by the federal government. And while Lustron Corp received a substantial allocation, sufficient steel was still hard to acquire. And what they could get was more expensive than anticipated.

Material acquisition issues plus slow production resulted in Lustron losing money on a daily basis. And it seems their financial woes get a bit more sticky. Even with hefty government loans, Lustron kept lobbying for more funding. They were even accused of paying a government official, Senator Joe McCarthy, to promote Lustron. Whoops.

By 1951, Lustron’s funding was recalled by the government’s Reconstruction Finance Corporation, totaling about $35-40m in government loans. Lustron filed for bankruptcy in 1954, marking the end of an ambitious venture that had aimed to revolutionize post-war housing.

Affordability

Like with most consumer products, the increase in cost for materials and transportation gets passed down to consumers (lucky us). And that increase didn’t make Lustron homes as affordable as originally promised. As noted above, the original goal for Lustron was to provide a house around $5,000.

However, by 1949, Luston house prices ballooned to around $8-10k (plus cost of foundation). In comparison, construction of a traditional frame house sold less than $10K total. Luston’s initial value proposition didn’t hold up.

Building Codes

Varying local and state building codes presented a significant barrier for Lustron homes. Even though porcelain-enameled steel outperformed conventional lumber for longevity, it failed to meet codes in some jurisdictions and therefore, couldn’t be built.

Lustron gave a good fight. They submitted places and specifications to local building authorities, and even lobbied on a national level for building code reform. But it wasn’t enough to make substantial change.

Homeowner Needs

We homeowners can be quite fickle, in all honesty. We want a maintenance-free house. But we also want the ability to change and remodel when we want to.

Well, that’s the problem with Lustron. You can’t paint them. You can’t remodel and add an addition. And homeowners second-guessed a home that couldn’t be tailored to their family’s needs. (but we still want low-maintenance)

We are complicated beings, aren’t we? 😂

12. Are Lustron Homes being Preserved?

Like most old houses, the passage of time has naturally taken its toll on Lustron homes. However, dedicated preservationists and homeowners have recognized the historical value of these unique homes and embarked on efforts to maintain and restore these steel-clad residences.

Some Lustron homes have been meticulously preserved by Lustron owners like Joe Williams and Kathryn Welch in St Louis, MO (timestamp 1:47 on the below video). These homeowners recognize they possess a rare piece of mid-century history and celebrate the unique experience. Some have even been turned into vacation rentals!

Preservation societies have risen to the occasion more than once to save a Lustron house. Some have even saved them from demolishing by buying, dismantling and moving them to new area where they have transformed into museums list this one in Closter, NJ (full list here) and community centers.

Numerous Lustron houses have been added to the National Register of Historic Places, which provides a level of protection against demolition.

Where Can You Nerd Out More?

The above post is merely the tip of the iceburg about Lustron Homes. To learn more, check out this website – Luston Research.

While the website is still under construction, it is still an amazing resource with facts, stories, photos, and videos compiled by Tom Fetters and Jean Fetters-Conner, who have spent over 35+ years researching Lustron homes. Tom is well-known in the Lustron community for his book The Lustron Home: The History of a Postwar Prefabricated Housing Experiment.

Related Posts

Want to be the first to know about new posts? Be sure to follow me on Pinterest, Facebook, Instagram or Twitter of even Etsy! Or better yet… Subscribe below!

My monthly (admittedly sometimes more, sometimes less….) emails are like receiving a unexpected letter from an old friend WITHOUT needing to put on your slippers and walk out to your mailbox…. See? I got ya, my friend!)

[Note: My posts are proudly connected to these amazing link parties full of DIY ideas and inspiration!]

There is a Lustron House Museum open to the public in Closter, NJ (NYC vicinity). It’s open every second Saturday of the month from noon to 2 p.m. and is free of charge to visit. The house is a Westchester Deluxe model and is fully furnished in authentic period furniture (1950-1970). http://www.lustronhouse.com

Jennifer – thank you so much for the info! I will add this link directly in the post. Much appreciated!